GMAW welding gasses are the gasses that are used in welding wire by GMAW welding gasses. The air that covers the arc to be replaced by a gas cover To prevent fouling of the welding melt pool. due to oxygen nitrogen and humidity in the air

udo.co.th The equipment center, grinding machines, grinding wheels and various tools for welding work of all kinds. We have a team of highly experienced professionals to give advice and consultation to all customers.

For example, the nitrogen contained in steel reduces the ductility and impact strength properties of the weld joint. and cause the weld to crack if there is nitrogen in the weld. A large number will also cause porosity. The steel with too much oxygen will combine with. The carbon in steel is in the form of carbon monoxide (CO) gas and is trapped in the steel, porous. Excess oxygen combines with other elements in the steel to form embedded compounds. in weld for the hydrogen produced by steam and oil Will combine with steel or aluminum, causing porosity, resulting in cracking of the weld.

To avoid fouling caused by such Can be done by using shielding gas There are 3 important shielding gasses, argon, helium and carbon dioxide, each of which can be used immediately. without mixing or can be mixed together

gas properties

The basic properties of hole gas used in welding are as follows:

- Thermal Properties at High Temperatures

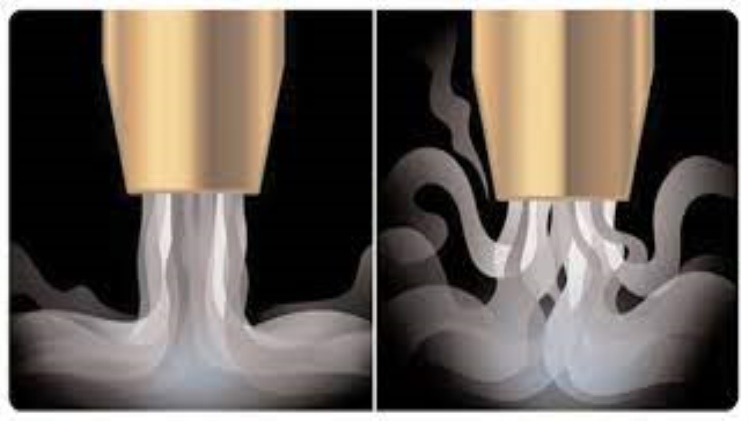

- A chemical reaction occurs between the gas and various elements mixed in the work metal and welding wire. 3 The form of metal transfer depends on the type of gas covering.

The thermal conductivity of gas at arc temperature affects the arc emf. and heat energy paid for welding As the heat conduction of the gas increases, the welding force must increase in order to can support the arc, for example gas helium and carbon dioxide has higher thermal conductivity

Argon gas For this reason, a large amount of heat is transferred to the weld. For celium gas and CO² gas, a high emf is required to maintain a uniform arc.

The gas to be used as a shielding gas must be compatible and suitable for the type of welding rod and piece. Welding work such as CO², and oxygen shielding gasses are not used to weld aluminum because of the formation of aluminum oxide. will help keep the arc even and the melting between the melting ponds with the texture of the material works well. Oxygen performs a better oxidizing function than CO², the consumption of oxygen mixed with argon is generally not more than 12% by volume.

For CO², and O², alloys can be used to weld steel where the welding wire must be deoxidized to prevent porosity in the weld. The choice of shielding gas also depends on the type of metal transfer and penetration depth.

and 2 e.g. Spray Arc metal transfer does not occur when shielding gas mixed with CO², or pure CO².

When mixing CO², more than 20%, a true Spray Arc cannot be formed. Only metal transfer will occur similar to spray transfer. If a shielding gas contains CO², up to 30% is required.

A high welding current makes it impossible to maintain a uniform arc. And there is also an increase in welding spatter (Sputter).

Argon gas (ARGON)

Argon is an inert gas with low thermal conductivity. Consequently, a narrow and high-intensity arc is generated, causing the work to receive high heat energy. Therefore, the resulting weld is narrower and penetrates better than using helium gas and CO², argon gas is the highest in the atmosphere, about 0.94%. It is non-flammable, colorless, odorless, and tasteless. Therefore, each cube of argon is prepared. Feet will need a lot of air. The price of argon is therefore much higher than that of oxygen and nitrogen. Argon can be stored in both liquid and gaseous conditions. The liquid argon is stored at The temperature is slightly below 184 degrees Celsius.

Argon gas has an Ionization Potential of 15.7 Volts (meaning that it takes 15.7 Volts to ionize atoms of gas). Argon gas is divided into the following acids:

Argon gas can be used as a shielding gas in its pure state. and mixed with other gasses to obtain the desired properties for welding steel and non-ferrous metals welding process All using pure argon gas and mixed argon. in order to increase the ability to weld, mechanical properties Arc properties and production Pure argon is used for welding. Non-ferrous metals include mainly aluminum, nickel alloys, copper alloys and alloyed metals. chemical reaction These include zirconium, titanium and tantalum. Argon provides excellent and consistent Spray Are. as well as good penetration and weld shape. For short circuiting welding, it can be done with thin sheet metal. But if welding iron metal is generally used. Argon is mixed with other gasses such as oxygen, helium, hydrogen, carbon dioxide and/or nitrogen.

HELIUM GAS (HELIUM)

Helium is an inert gas that is lighter than argon. And conducts heat better than argon gas when heated will spread out thus causing the intensity of the arc energy to penetrate into the weld metal than argon gas, therefore, the welding seam is wider and has less penetration depth, and helium gas is obtained from the natural gas production process. It is a non-flammable, odorless, tasteless, colorless gas with a ionization potential of 24.5 Volts, about 17 times the weight of air. Helium gas is used for applications requiring a large amount of heat. To achieve water flow, wetting, high penetration and high welding speed, GMAW helium gas welding provides a consistent arc. lower than using argon gas Helium gas is not used to weld aluminum because the cleaning reaction is not as good as argon gas. But it is recommended to use thick aluminum welding. The arc beam of helium gas is wider than that of argon gas. Thus making the thickness reduced current tightness Therefore, the moving force must be increased. which causes heat (Heat Input) to be higher than welding with argon gas But the flow of metal water will be better. This advantage is suitable for Used to weld aluminum, magnesium and copper alloys.

Liam gas is usually mixed with argon gas. In different percentages in order to bring the advantages Of the two gasses, argon gives a uniform arc and has a good cleaning reaction. While helium gas provides the flow of water, the welding wire sticks to the workpiece well.